How Much Does a Ford 302 Engine Weigh?

The Ford 302 engine is well-known for its strong performance and versatility in various vehicles. One key factor to consider when using or upgrading this engine is its weight, as it can impact the car’s handling, balance, and efficiency. The weight of a Ford 302 depends on its materials and any extra parts like intake manifolds or carburetors. Knowing the weight helps car owners make better choices for their projects, whether they are restoring a classic car or upgrading a modern one.

A Ford 302 engine weighs around 460 pounds (209 kg) in its stock form with cast iron components. If aluminum parts are used, the weight can drop to about 375 pounds (170 kg). The exact weight depends on the configuration, including accessories like the intake manifold and carburetor.

In this article we will discuse “How Much Does a Ford 302 Engine Weigh? “.

Table of Contents

Understanding the Ford 302 Engine

Brief History of the Ford 302

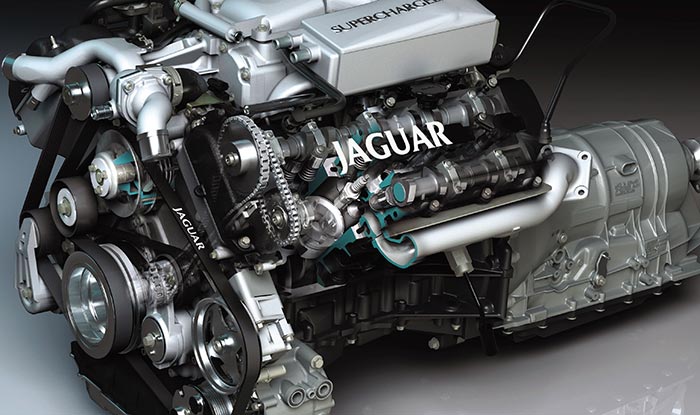

The Ford 302 engine was first introduced in 1968 as part of Ford’s small-block V8 lineup. It became popular for its power, durability, and use in vehicles like the Mustang and F-150. Known for its performance and easy customization, the 302 engine remains a favorite for car enthusiasts and restoration projects.

Also read: What Does Service Beltminder Mean in a Ford Transit?

Origins in the 1960s

The Ford 302 engine was introduced in the late 1960s as part of Ford’s small-block V8 family. Designed for performance and reliability, it quickly became a favorite for cars like the Mustang and other Ford models, offering a balance of power and efficiency for everyday driving and racing.

Popular Applications in Ford Vehicles

The Ford 302 engine was widely used in vehicles like the Mustang, Bronco, and F-150. Its strong performance and reliability made it a top choice for sports cars, trucks, and SUVs, serving both everyday drivers and racing enthusiasts.

Key Features of the Ford 302 Engine

The Ford 302 engine is a small-block V8 known for its compact size, reliable performance, and versatility. It delivers a good balance of power and efficiency, producing up to 290 horsepower in some models. Its simple design makes it easy to customize, repair, and fit into a variety of vehicles.

Specifications Overview

The Ford 302 engine is a V8 with a displacement of 302 cubic inches (4.9 liters). It features a 4-inch bore and a 3-inch stroke. Depending on the model, it produces around 200 to 290 horsepower. Its design allows for easy upgrades and works well in both performance and daily driving.

Versatility and Performance

The Ford 302 engine is known for its versatility and strong performance. It works well in various vehicles, from sports cars to trucks. With easy modifications, it can provide more power and efficiency. Its design makes it suitable for both daily driving and high-performance use, making it a popular choice.

The Weight of the Ford 302 Engine

Average Weight

The average weight of a Ford 302 engine is around 460 pounds (209 kg) when it has cast iron components. If the engine is fitted with aluminum parts, it can weigh about 375 pounds (170 kg). The weight may vary depending on additional parts and modifications.

Factory Stock Weight

The factory stock weight of a Ford 302 engine is about 460 pounds (209 kg). This weight includes the standard cast iron block and components, which can vary slightly depending on the vehicle or specific model it is used in.

Variations in Weight Due to Configurations

The weight of a Ford 302 engine can vary based on its configuration. For example, engines with aluminum components are lighter than those with cast iron parts. Additional accessories like the intake manifold and carburetor can also affect the overall weight.

Comparing to Other Engines

When compared to other engines, the Ford 302 is lighter than many big-block V8 engines, which can weigh over 600 pounds. However, it is heavier than some newer, smaller engines, such as four-cylinder or six-cylinder engines, which are typically more lightweight and fuel-efficient.

Small Block Engines

Small block engines are compact V8 engines known for their lighter weight and efficient design. They typically have a displacement of 262 to 400 cubic inches. These engines offer a good balance of power and fuel efficiency, making them popular in many cars and trucks.

Big Block Engines

Big block engines are large, powerful car engines with a bigger displacement, often used in trucks and muscle cars. They provide more torque and horsepower, making vehicles faster and capable of carrying heavy loads.

Factors Influencing Engine Weight

Material Composition

Material composition refers to the types of materials used to make an object or product. It describes the different substances, like metals, plastics, or ceramics, and how they are combined to create the final product. This information helps understand the object’s strength, weight, durability, and overall performance.

Also read: Ford Phone as a Key Not Working 2k24

Cast Iron vs. Aluminum

Cast iron is heavy, durable, and good for high-heat applications, but it’s brittle. Aluminum is lighter, resistant to corrosion, and easier to mold, but less durable. Both materials have different uses depending on strength, weight, and environmental conditions.

Additional Components

Additional components refer to extra parts added to a main system or product to improve its function or performance. These can include things like sensors, cables, or attachments that work together to enhance overall efficiency and capability.

Intake Manifold and Carburetor

The intake manifold is a part of the engine that directs air into the cylinders. The carburetor mixes air with fuel before it enters the engine. Together, they help the engine run smoothly by ensuring the right air-fuel mixture for combustion and performance.

Accessories and Mounting Hardware

Accessories and mounting hardware are extra parts used to support and enhance the main system or product. Accessories can include items like covers or lights, while mounting hardware includes bolts, screws, and brackets that help secure parts together, ensuring proper function and stability.

Practical Implications of Engine Weight

Impact on Vehicle Performance

The impact on vehicle performance refers to how different parts and features affect how well a vehicle runs. This includes speed, fuel efficiency, handling, and comfort. Changes to the engine, tires, or suspension can improve or reduce overall performance based on the vehicle’s design and purpose.

Also read: How Long Does It Take Ford to Build a Bronco?

Handling and Balance

Handling and balance refer to how well a vehicle responds to steering and stays stable on the road. Good handling makes the car easy to control, while balance ensures the weight is evenly distributed, helping the car stay steady during turns and stops for a smoother, safer drive.

Fuel Efficiency

Fuel efficiency refers to how well a vehicle uses fuel to travel a certain distance. A vehicle with high fuel efficiency consumes less fuel, allowing it to travel farther on the same amount. This helps reduce fuel costs and lowers the vehicle’s environmental impact.

Choosing the Right Engine for Your Vehicle

Choosing the right engine for your vehicle depends on factors like power, fuel efficiency, and the type of driving you do. A smaller engine is good for city driving, while a larger engine offers more power for highway driving or towing. Consider your needs and budget when selecting.

Modifications and Weight Changes

Lightweight Modifications

Lightweight modifications involve changing parts of a vehicle to reduce its weight. This can include replacing heavy materials with lighter ones, such as using carbon fiber or aluminum. Lighter vehicles can improve speed, fuel efficiency, and handling by reducing the load the engine needs to carry.

Replacing Cast Iron with Aluminum Components

Replacing cast iron with aluminum components helps reduce a vehicle’s weight. Aluminum is lighter, which improves fuel efficiency and performance. It also resists rust better than cast iron. However, aluminum may not be as strong or durable in certain high-stress parts, so it’s important to consider the application.

Other Weight-Reduction Strategies

Other weight-reduction strategies include using lighter materials like carbon fiber, removing unnecessary parts, and replacing bulky components with smaller, lighter alternatives. Upgrading to lighter wheels, using thinner glass, and reducing interior features also help decrease weight, improving speed, fuel efficiency, and overall vehicle performance.

Performance vs. Weight Trade-Off

The performance vs. weight trade-off means finding a balance between a vehicle’s power and its weight. Reducing weight can improve speed and fuel efficiency, but too much reduction may sacrifice strength or stability. The key is to adjust weight carefully without harming the vehicle’s overall performance.

Conclusion

In conclusion, the Ford 302 engine weighs about 460 pounds (209 kg) with cast iron components and 375 pounds (170 kg) with aluminum parts. The weight can vary depending on modifications and additional components. Choosing the right engine weight can improve vehicle performance, handling, and fuel efficiency.

FAQs

What is the weight of a Ford 302 engine with aluminum components?

A Ford 302 engine with aluminum components weighs around 375 pounds (170 kg), making it lighter than the version with cast iron parts, which weighs about 460 pounds (209 kg).

How does the Ford 302 compare in weight to newer engines?

The Ford 302 engine is heavier than newer smaller engines, like four-cylinder or six-cylinder models, which are often lighter and more fuel-efficient, but it is lighter than larger big-block V8 engines.

Can reducing engine weight improve performance?

Yes, reducing engine weight can improve performance by increasing speed, handling, and fuel efficiency. Lighter engines put less strain on the vehicle, leading to better overall performance and control.

What vehicles are compatible with the Ford 302 engine?

The Ford 302 engine is compatible with vehicles like the Ford Mustang, F-150, Bronco, and various other classic Ford models. It can also be used in custom builds and restorations.

Are there downsides to using lighter materials in an engine?

Using lighter materials in an engine can reduce strength and durability. Some lighter materials, like aluminum, may not handle high stress as well as heavier, stronger materials, potentially affecting engine performance and lifespan.

One Comment