How Long Does It Take Ford to Build a Bronco?

The Ford Bronco is a popular SUV known for its strong design and off-road features. Many people wonder how long it takes to build this impressive vehicle. The time depends on factors like demand, customization, and production processes. Understanding the steps and challenges in Bronco production can provide helpful insights.

It takes about 10 to 12 hours to build a Ford Bronco on the assembly line. However, the total time from order to delivery can take weeks or months due to factors like demand, customization, and supply chain issues. Ford builds most Broncos at the Michigan Assembly Plant.

We’ll talk about “How Long Does It Take Ford to Build a Bronco?” in this article.

Table of Contents

The Ford Bronco Manufacturing Process

Overview of the production stages

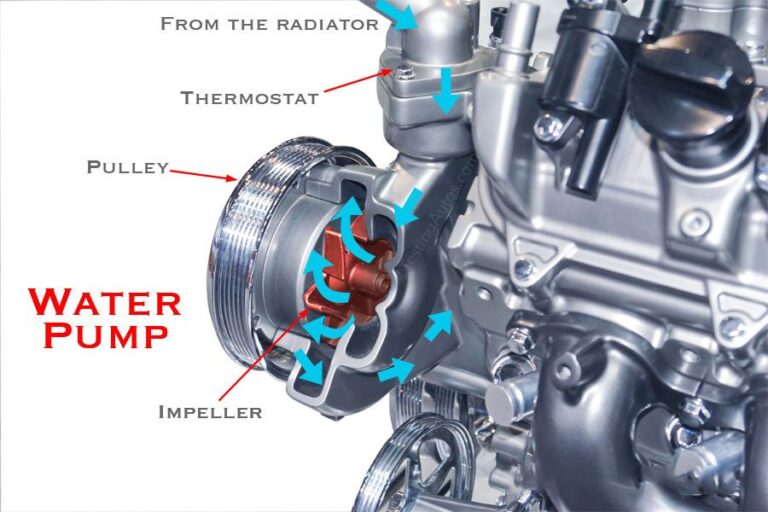

The production of a Ford Bronco includes several stages: stamping the metal parts, welding the body, painting, and assembling the components. Each step is carefully managed to ensure quality and efficiency. Modern technology, like robotics, is used to speed up the process and maintain high standards during production.

Also read: How Much Does a Ford 460 Engine Weigh? Get Informed 2024!

The role of assembly plants

Assembly plants play a key role in building vehicles like the Ford Bronco. They handle tasks like welding, painting, and assembling all parts into a complete car. Using advanced machines and skilled workers, these plants ensure the process is efficient and meets quality standards. The Michigan Assembly Plant builds most Broncos.

Key Factors That Affect Production Time

Supply chain and materials

The supply chain and materials are important for building the Ford Bronco. Parts like steel, engines, and electronics must be delivered to the assembly plant on time. Production can be slowed by supply chain delays or shortages. The availability of the appropriate materials when needed is guaranteed by effective management.

Customization and trim levels

Customization and trim levels affect the production of the Ford Bronco. Customers can choose from different trims, like Base, Wildtrak, or Raptor, and add features such as roof options or advanced packages. These choices can increase production time, as specific parts and adjustments are needed to match the order.

Demand and production capacity

Demand refers to how much of a product people want to buy. Production capacity is the maximum amount a company can make in a certain time. If demand is higher than production capacity, there may be shortages. If capacity is higher than demand, companies might produce more than needed, leading to waste or extra costs. Balancing both is important for business efficiency.

Average Time to Build a Ford Bronco

Insights from Ford’s assembly lines

Comparison to other vehicles in the same segment

When comparing vehicles in the same segment, factors like price, features, fuel efficiency, and safety are important. Some cars may offer better technology, while others might focus on comfort or speed. It’s essential to consider what matters most to the buyer, such as reliability or performance, to choose the best option in that segment.

Customization and Special Orders

How custom features impact build time

Custom features can increase build time because they require additional design, coding, and testing. Each feature needs to be tailored to specific needs, which takes more time compared to using standard options. The complexity and number of custom features can further lengthen the process, affecting both development and quality assurance stages of the build.

Also read: Ford Vehicle Tracking Not Working: Troubleshooting Guide

Popular customizations and their production implications

Popular customizations include adding unique designs, special features, or advanced functions. These can affect production time and cost. More custom options may require extra resources for design, testing, and manufacturing. They can also lead to longer lead times, increased complexity, and higher costs. Customization needs careful planning to ensure it does not delay the production process.

Delays in Production

Common causes of delays

Common causes of delays include poor planning, lack of resources, unexpected technical issues, and changes in project scope. Weather problems, supply chain disruptions, and miscommunication can also lead to delays. When tasks take longer than expected or team members face challenges, it can push back the overall timeline, affecting project completion.

Global supply chain challenges

Global supply chain challenges include delays in shipping, high transportation costs, and shortages of raw materials. Political issues, natural disasters, and trade restrictions can also disrupt the flow of goods. These problems make it harder to meet demand and increase costs for businesses. Companies must find ways to adapt and improve their supply chain management to reduce these risks.

Behind the Scenes: The Michigan Assembly Plant

Overview of the primary plant for Bronco production

The primary plant for Bronco production is located in Michigan, USA. It handles the assembly of the Ford Bronco, from body construction to final checks. The plant uses advanced technology and skilled workers to ensure high-quality production. This facility plays a key role in meeting the demand for Bronco vehicles and supports the brand’s commitment to innovation and performance.

Innovations in the assembly process

Innovations in the assembly process include the use of robotics for precision and efficiency, 3D printing for faster prototyping, and smart sensors to monitor quality. These advancements help reduce errors, speed up production, and improve safety. Automation and advanced software also allow for better tracking of parts and faster decision-making, making the overall process more efficient and cost-effective.

How Technology Speeds Up Production

Use of robotics and automation

Robotics and automation are used to improve efficiency and accuracy in production. Robots can handle repetitive tasks like welding, painting, and assembling parts, reducing human error. Automation systems track progress and manage workflows, speeding up processes. This technology increases production speed, lowers costs, and enhances safety by reducing the need for workers to perform dangerous tasks.

Also read: Ford SYNC Microphone Not Working: A Comprehensive Guide 2024!

Quality assurance processes

Quality assurance processes ensure that products meet required standards. This includes checking raw materials, monitoring production steps, and testing finished products. Regular inspections and testing help find any defects or issues. The goal is to make sure the product is safe, reliable, and performs as expected. These processes reduce mistakes and improve customer satisfaction.

Bronco Trim Levels and Their Impact on Build Time

Differences between base and higher trims

Base trims have standard features, offering basic options and simple designs. Higher trims include extra features like advanced technology, better materials, and more customization options. These upgrades often improve comfort, performance, and appearance. Higher trims are more expensive due to the added features and enhanced overall quality.

Time estimates for premium trims like Wildtrak or Raptor

Time estimates for premium trims like Wildtrak or Raptor depend on the complexity of customization and demand. These models may take longer to build and deliver because of their advanced features and limited availability. Typically, it can take several weeks to a few months for production and delivery to be completed.

Ford’s Commitment to Quality

Ensuring durability and performance

Ensuring durability and performance involves using high-quality materials, rigorous testing, and advanced engineering. Regular checks during production help identify potential issues early. Strong designs and quality control processes make sure the product lasts longer and works well under different conditions, providing reliability and satisfaction for the user.

How quality checks impact timelines

Quality checks can impact timelines by adding extra time for inspections and testing. While they help ensure the product meets standards, they may delay production. If issues are found, more time is needed for repairs or adjustments. However, these checks prevent larger problems, ensuring better quality and fewer returns later.

Customer Waiting Time

What customers can expect from order to delivery

Customers can expect a smooth process from order to delivery. After placing an order, they will receive updates on production and shipping. Delivery schedules differ based on the item. and location. The company aims to deliver high-quality items on time, with customer service available for support throughout the process.

Average lead time for different regions

The average lead time for different regions varies based on factors like location, transportation, and supply chain efficiency. Some areas may experience faster delivery times, while others might have longer waits due to distance or infrastructure. Understanding regional differences helps businesses plan better and improve customer satisfaction.

Improvements in Bronco Production Over Time

Lessons learned from initial launches

Lessons from initial launches show the importance of careful planning and testing. Early feedback helps identify issues with design, production, or customer experience. These insights allow companies to make improvements, reduce errors, and better meet customer needs in future product releases, ensuring smoother launches ahead.

Adjustments made to streamline the process

Adjustments to streamline the process include improving communication, simplifying workflows, and using better technology. These changes reduce delays and errors, making production faster and more efficient. By focusing on key steps and removing unnecessary tasks, companies can save time and resources, leading to smoother operations and better results.

Conclusion

In conclusion, the production time for a Ford Bronco depends on various factors such as demand, customization, and supply chain challenges. While it typically takes around 10-12 hours on the assembly line, delays can occur due to high demand or specific customizations. Ford uses advanced technology and quality checks to ensure the final product meets high standards. Customers can expect updates throughout the process and should be aware of regional variations in delivery times.

FAQs

How long does it take to receive a Bronco after ordering?

The time to receive a Bronco after ordering can vary, usually taking several weeks to a few months. Factors like demand, customization, and production delays can affect delivery times.

Can I expedite my Bronco order?

It may be possible to expedite your Bronco order, depending on availability and production schedules. Contact your dealer to ask about faster delivery options or any priority processing for your order.

Are certain Bronco trims faster to produce?

Yes, certain Bronco trims may be faster to produce. Simpler models with fewer custom features often have shorter production times compared to higher trims with more complex options or special features.

What happens if there’s a delay in my Bronco’s production?

If there’s a delay in your Bronco’s production, the dealer will usually inform you about the new estimated delivery time. You may also receive updates or options to adjust your order.

Does Ford provide updates during the production process?

Yes, Ford typically provides updates during the production process. Dealers may inform you about important milestones or delays, and you can check the status of your order through the dealer or online.